Digital Transformation

The Digital Economy

As product design, logistics and supply chain professionals prepare for the future, they will have to deal with continuous upgrades in technology as well as the growing importance of digital technology and “big data” solutions. According to IDC, by 2020, 50% of G2000 companies will see a majority of their business depend on their ability to create digitally-enhanced products, services and experiences.

As with the Cloud, it’s not a matter of “if” you will be moving to digital products and experiences, but rather “when.” By 2019, enterprises worldwide are expected to spend $2.1 trillion on digital transformation technology and services. Centered around Internet of Things technology (or simply IoT), digital transformations will be focused on harnessing the power of inexpensive sensors networked together via the Internet. While IoT is reaching a level of maturity in certain sectors – such as “smart cities” with solutions such as sensor-driven parking solutions or “smart homes” with connected lighting or heating solutions – harnessing the data from these devices is still immature.

Blueprint for Digital Success

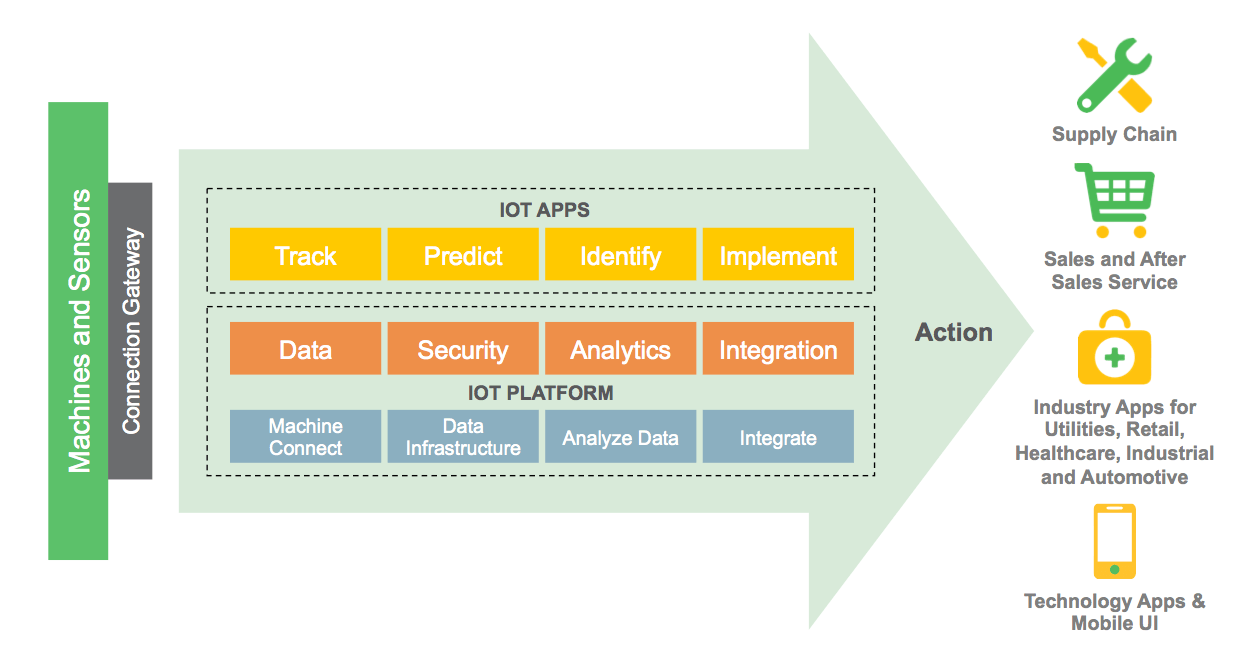

Working with our partners at Oracle and GE Digital, we have developed a strategic blueprint to help our customers begin migrating to the digital economy.

Digital Strategy Services

The biggest challenge with digital transformation lies not in deployment of the sensors themselves, but rather in harnessing, curating and analyzing IoT data in order to improve business processes, services and product offerings. In the supply chain arena, although we have seen quite a bit of progress related to warehousing and in-transit visibility through GPS and RFID solutions, there’s still a massive amount of innovation on the horizon that can be achieved through digital transformation.

Here at Inspirage, we believe the secret to harnessing this powerful technology will be through strategic use of master data management and predictive analytics. And the benefits of adopting digital solutions can be game changing.

Innovation Solutions |

Supply Chain & Logistics Solutions |

Manufacturing Solutions |

| Sensor data coming back from customers can help improve the product development process. | Leveraging IoT data, supply chain leaders can address many planning and distribution challenges such as: | With our IoT-enabled manufacturing solution, customers can realize dramatic reductions in data entry and labor costs by: |

|

|

|

GE Digital Partnership

Working with GE Digital, Inspirage can help you leverage the power of Industrial Internet of Things (IIoT) technology. GE Digital’s technology securely connects machines, data, and analytics to improve operational efficiency. The focus of the IIoT is on connecting industrial assets, such as turbines, jet engines, and locomotives to the cloud and to each other in meaningful ways. As a leading manufacturer of industrial assets, GE is in a unique position to leverage its understanding of asset models and industrial operations to create new value for industrial customers. The GE platform provides a set of development tools and best practices that rapidly enable those customers to bridge the gap between software and operations to drive incredible value and innovation.

Working with GE Digital, Inspirage can help you leverage the power of Industrial Internet of Things (IIoT) technology. GE Digital’s technology securely connects machines, data, and analytics to improve operational efficiency. The focus of the IIoT is on connecting industrial assets, such as turbines, jet engines, and locomotives to the cloud and to each other in meaningful ways. As a leading manufacturer of industrial assets, GE is in a unique position to leverage its understanding of asset models and industrial operations to create new value for industrial customers. The GE platform provides a set of development tools and best practices that rapidly enable those customers to bridge the gap between software and operations to drive incredible value and innovation.

Oracle Digital Partnership

Once you have your IoT data in hand, you can harness its power through Oracle IoT Applications. Inspirage can help you leverage these solutions to get smart with predictive, machine learning algorithms and quickly extend core SCM and ERP processes—with real-time IoT data and insights.

Once you have your IoT data in hand, you can harness its power through Oracle IoT Applications. Inspirage can help you leverage these solutions to get smart with predictive, machine learning algorithms and quickly extend core SCM and ERP processes—with real-time IoT data and insights.

IoT Asset Monitoring Cloud

Optimize the enterprise supply chain and improve customer experience with real-time, intelligent insights from connected assets to drive predictive maintenance, optimized SCM, and improved customer experiences. With this solution you can:

- Monitor Assets – Track any asset, anywhere, anytime, indoor or outdoor, and achieve ROI in days

- Digitize Physical Assets – Instantly transform assets into digital twins, and intelligently monitor the assets’ health, location, and utilization

- Predictive Maintenance – Predict asset and equipment failures before they happen, and minimize the unplanned downtime

IoT Production Monitoring Cloud

Leverage best-in-class production monitoring for factories, products, and machines

- Digital Manufacturing Twin – Gain real-time visibility through the digital transformation of factories and operations

- Prescriptive Analytics – Improve machine and factory uptime with machine learning models

- Manufacturing and SCM Integration – Integrate seamlessly with manufacturing and supply chain systems, enabling you to act on decisions without doing manual entries

Drive fleet efficiency with real-time monitoring of vehicles, drivers, and trips. Gain real-time visibility into vehicle location, costs of operation, vehicle usage, and driving behavior.

- Real-Time Fleet Visibility – Get real-time vehicle location, status, and health—all at your fingertips

- Digitally Transform Fleets – Instantly connect your fleet and digitally transform your logistics operations

- Improved ETA Predictions – Improve customer experiences with better ETA predictions and its impact on the supply chain

- Integrated with Supply Chain – Built to optimize transportation and logistics processes